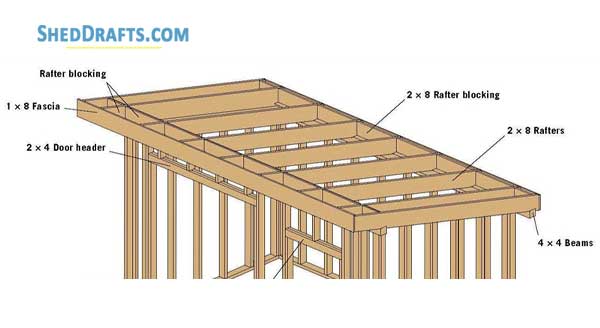

Framing the roof is the most complex step involved in the construction of a shed. Reading about the different roof component names, joinery techniques, and roof styles will make it much easier for any DIY carpenter to craft the roof frame in a few weekends.

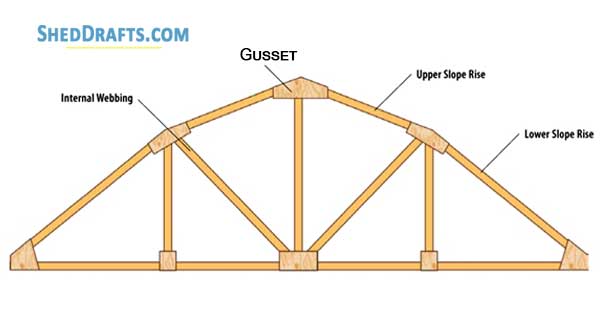

A truss is a roof section built by fastening two or more rafters at an angle over a horizontal chord. You can build the roof trusses on the ground and hoist them into place or build each individual component, like the ceiling joists, collar ties, ridge board, and rafters, one at a time.

If you build trusses, you can assemble the roof faster, but you will need assistance for hoisting the components. If you build the roof piece by piece, you can hoist it yourself, but it will take many trips climbing up and down to put all the pieces into place.

There are five types of roof styles commonly used in shed construction.

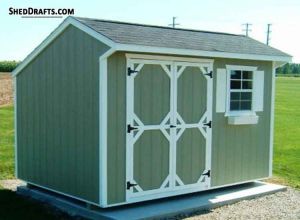

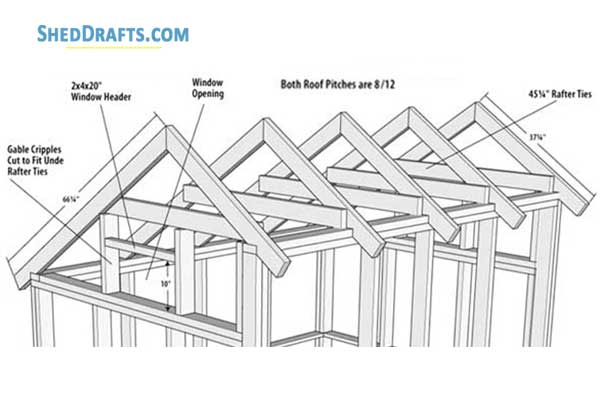

Gable Roof (A-Frame Style)

A double-pitched roof with two sloping sections that meet at a central ridge line is known as a gable or a-frame roof. This is the most commonly used roof design for sheds. The rafter ends are cut at an angle and fastened to a central ridge board at the peak.

Ridge boards are usually framed using 1×8 lumber, and 2×6 lumber is used to frame the rafters. You can choose to avoid using the ridge board and directly secure the rafters using gusset plates.

Gable roofs are usually built with a pitch between 40 and 45 degrees.

Lean-To Roof (Skillion or Shed Style)

A single-pitched roof that only slopes in one direction is known as a skillion, lean-to, or shed-styled roof. This is the simplest roof design you can build for the shed. It is the recommended style for beginners who are assembling their first shed.

This roof style is used both for freestanding structures as well as for sheds that share a wall with an existing building, like a barn, garage, or house. Because of its simple design, this roof can be built at a low cost in a short time.

Lean-to roofs usually have a shallow pitch between 18 degrees and 33 degrees.

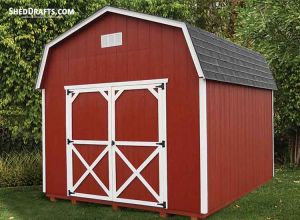

Gambrel Roof (Barn Style)

The unique gambrel roof style looks like a barn and has a double-pitched roof with two distinct slopes on either side. The shorter slopes closer to the peak have a shallow pitch, and the slopes that connect to the walls are more steeply pitched.

Framing a gambrel roof is a complex task and is not for beginners. Because of the extra rafters and materials needed, the construction time and cost of building this roof are higher than the lean-to or gable roofs.

This roof provides ample storage space underneath the rafters and allows you to build a loft. The doors in a gambrel shed are usually built into the end walls because the roof will overhang the side walls.

Hip Roof

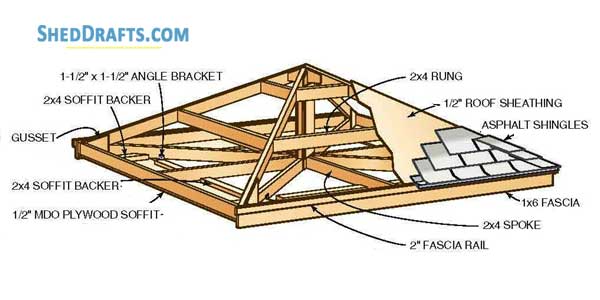

A hip roof has four equal sloping sections along each of the four walls of the shed. This is one of the sturdiest roof designs that can resist heavy snow loads and strong winds.

Because of their intricate design and the need for more rafters, this is one of the most challenging and costliest roofs to build.

Saltbox Roof

A double-pitched roof that has one sloping section longer than the other so that the peak is off-center is known as a saltbox roof. The peak of a saltbox roof will always be closer to one wall than the other.

This style usually has a pitch of 45 degrees, and the roof’s peak is usually kept towards the front wall, around one-third of the distance between the two opposite walls.

How To Select The Best Roof Style For Your Shed

If you are new to building sheds or have a tight budget, then the gambrel and hip roof designs are not recommended. These designs are only suitable for experienced carpenters.

Here are some of the advantages of gable and lean-to styles.

Lean-To

- Ideal design for first-time shed builders

- Low building costs

- Allows snow and rain to slide off quickly

- Solar panels or skylights can be installed easily

Gable

- Provides more attic space than a lean-to

- Simple rafter layout suitable for amateur builders

- More resistant to strong winds compared to lean-to

- Steeper roof slope allows faster water drainage

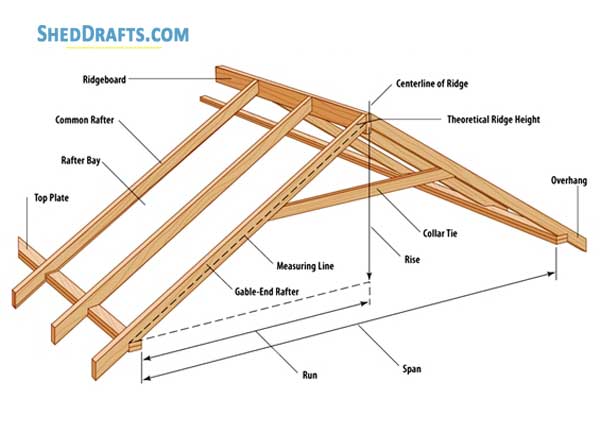

Important Roof Terminology

Let us look at some of the common roof terms you should quickly get familiar with.

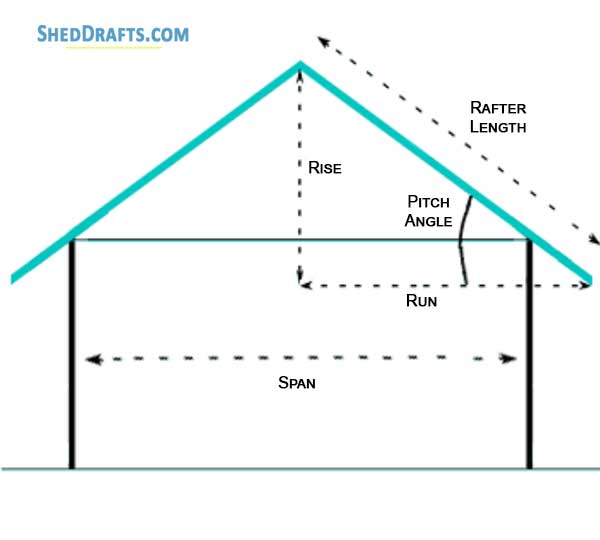

- Span is the distance measured horizontally between two opposing walls, not including the overhangs.

- Rise is the vertical height between the roof’s peak (ridge) and the end wall’s top plate.

- Run is usually half the span. It is the horizontal distance between a point below the ridge and a side wall.

- Pitch is the angle at which a roof is sloping. It is measured as a ratio of rise and span. For, e.g., a gable roof that has a rise of 2 feet and a span of 8 feet has a pitch of 2/8 or ¼.

- Slope is the ratio of the roof’s unit rise to its unit run. For a roof that rises 10 inches for every 12 inches of run, the slope would be expressed as 10-in-12. This slope would usually be shown in blueprints as a right-angled triangle with the number 12 on top and 10 at the bottom and the angle of the hypotenuse showing the pitch.

Choose The Best Wood For Your Roof’s Substrate

The roof substrate, decking, or sheathing is the surface to which the roofing materials are attached.

A roof system is generally made up of several membranes that include the bottom-most sheathing underlayment or cover boards, then a thermal insulation layer, and finally, a waterproof layer like shingles.

Commonly used roof decking materials include

- Gypsum Boards

- Solid Timber Boards

- Perlite

- Metal Panels

- High-Density Polyisocyanurate

- Plywood/OSB/CDX

The sheathing is attached to the rafters by staggering the cover boards and aligning them in rows.

There are two types of wooden cover boards that are most commonly used as sheathing in shed roofs: OSB and CDX.

Exterior Grade Plywood (CDX)

CDX plywood is designed for exposure to outdoor weather conditions.

It is created by gluing together thin veneer-like layers of wood with the grain of each layer perpendicular to the next layer. This creates a sturdy structure that resists twisting and bending. The X in CDX stands for exposure, and the C and D are plywood grades of the first and last layers that are sandwiched together.

CDX is not fully waterproof but is much more resistant to moisture than ordinary plywood.

Oriented Strand Board (OSB)

OSB is crafted by mixing together tiny wooden strands with a waterproof resin and bonding them together at high temperatures. OSB is quite durable and comparable in strength to CDX, but It is more prone to splitting and warping over time. It is also less moisture resistant compared to CDX.

Differences between CDX and OSB

CDX is costlier than OSB and is more water resistant.

OSB will absorb and hold water like a sponge when exposed to moisture for long periods of time. And it will take a long time to dry. This will damage the wood over time.

CDX dries faster as it doesn’t absorb that much water. It is also lighter than OSB but provides the same amount of durability.

If you are building in a region that doesn’t receive much rain or snow, then OSB is good enough for you. CDX is suitable if you know the roof is going to be exposed to a lot of moisture.

Which Lumber To Use For Rafters: 2×4 Or 2×6?

For roofs with a pitch steeper than 3/12, it is sufficient to use 2×4 timber. For lower-pitched roofs, you should use 2×6 lumber because these roofs need more support.

Trusses are usually built by fastening 2×4 lumber together.

Even though 2×6 timber may be costlier, it is more durable than 2×4 and allows you to space out the rafters with larger gaps. If you live in a place with heavy snow or winds, then it is always better to use 2×6 lumber to craft the roof.

Durable Roofing Materials For Your Shed

Here are the most commonly used roofing materials that protect your shed from the elements and also enhance its aesthetic beauty.

Polycarbonate Panel

Polycarbonate roofing panels are 30 times stronger than acrylic and are highly durable. They can bear intense heat and extremely cold weather. This high quality comes at a greater price as these panels are much more expensive than other options.

Fiberglass Mineral Surface Roll Roofing

Mineral Surface Roll Roofing, or MSR, is made of rubberized asphalt and fiberglass. Its surface is coated with granules of minerals to make it water and heat-resistant. It comes in low-cost rolls of 100 square feet. MSR can be easily installed on most shed roofs with a low pitch.

Asphalt Shingles

Asphalt or Architectural shingles contain multiple layers of laminated asphalt. They are very commonly used as roofing materials for both residential buildings and storage structures due to their beauty and durability.

Board-On-Board And Board-And-Batten

The board-on-board roofs consist of two layers of boards arranged vertically. Gaps between the boards in the lower layer are covered by the boards in the upper layer. Both board layers contain grooves to allow water to flow off.

Board-and-batten roofing consists of vertical boards installed perpendicular to the slope of the roof. The boards are fastened to horizontal battens that have grooves for water drainage.

Originally these types of roofs were made with wood, but now synthetic materials are also used.

Shakes Or Wooden Shingles

Shakes are shingles made of woods like cedar that provide much better heat insulation than asphalt shingles.

They are also suitable for areas that receive hail and have a steady freeze and thaw cycle over the seasons. Shakes are also resistant to insects and make the shed look more beautiful.

They can be expensive, though, and require maintenance to clear out mold and moss every few years. Shakes are also more prone to catch fire, so they are not suitable for areas with very high temperatures.

Metal Sheets

Metal sheeting is quite durable and often outlasts wood-based roofing materials. They are much lighter than wood, highly weather resistant, and often come with warranties of more than 45 years. The only downside is that they are somewhat expensive.

3-Tab Shingles

Three-tab shingles are much lighter and cheaper than architectural singles. They are often used by DIY builders because of their low-cost and simple installation process.

Is MSR The Cheapest Method To Roof A Shed?

MSR is the recommended roofing material for DIY builders who want to keep costs low and still want a sturdy, weather-resistant roofing solution. It’s less expensive than shingles and can easily be unrolled and nailed onto any roof slope.

How To Waterproof Your Shed’s Roof

Water Is a shed’s biggest enemy. Rain, snow, and humidity all have a way of slowly and surely damaging your shed roof and entering inside.

Once moisture gets inside, it will ruin the stored items and cause the growth of mold. So, it is vital to waterproof the roof to ensure the safety of the gear stored inside.

Here are some critical points to note to guarantee your roof remains weatherproof.

- Pick a roof design with a steep slope so that water drains off quickly

- Install an underlayment of felt or tar paper over the sheathing before attaching shingles.

- Let the roof overhang the walls by at least 10 inches so that the run-off water remains away from the walls.

- Install drip edges and gutters on your roof to allow water to be carried away quickly with minimum splashing.

With the right planning and materials, you can easily build a durable shed roof even within a tight budget. Now let us look at how to add sheathing and siding to your shed exterior.