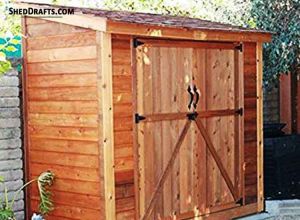

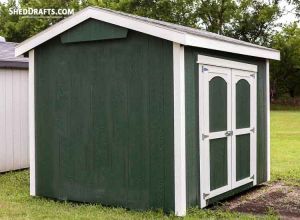

Select from over large collection of shed plans that are designed to meet all of your storage needs. Our blueprints will help you craft small or spacious wooden outbuildings as per your needs.

Whether you want to build a small storage shed in your garden or set up a large backyard workshop, our plans provide the guidance to assemble your outdoor room quickly.

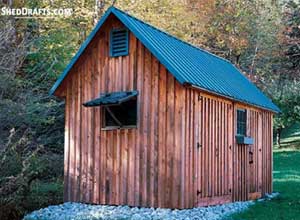

With some simple measurements, basic construction tools, and quality lumber, you can frame your own lean-to, gable, gambrel or saltbox shed the DIY way in no time.

Index Of All Building Designs

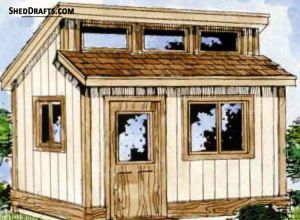

Use these drawings to craft a durable wooden 10×12 shed. Blueprints for building outdoor sheds in larger sizes are also available below. The material list included will each plan allows you to arrange all the items needed for construction in your backyard before you begin and to estimate costs.

Whether you want to build a small timber shed for storing your gardening tools or craft a greenhouse that can be used as a potting shed, our plans will allow you to create any design from floor to roof. You can also construct a larger building with a wooden porch that can be used to hang plants or as a lounging area.

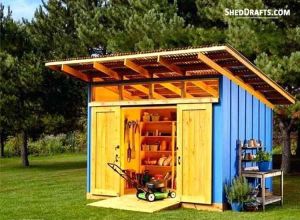

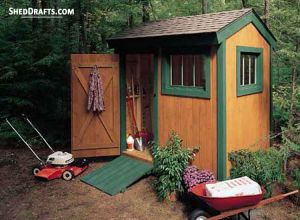

Our detailed DIY plans can be used to build small or large backyard sheds for storing anything from firewood to bikes. You can also use it to construct a she-shed or man-cave in your garden that will act as your personal retreat. Make a small tool shed or a spacious exercise shed. Anything is possible using this wide range of blueprints.

These blueprints may be used for creating huge storage areas that also double as living spaces.

You can build a simple firewood shed with these plans or create a handy tool storage area.

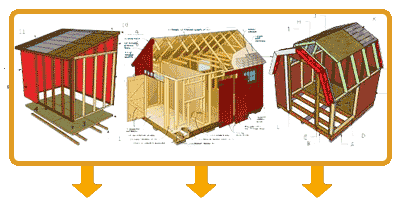

How to Build a Shed From A to Z The DIY Way (Quick Overview)

Shed Foundation And Floor Frame Assembly

Here are the common components, terms, and processes involved in creating a shed foundation and floor frame.

Backfill

The gravel used to pack the gap between a foundation wall and the ditch excavated around it is called backfill.

Concrete necklace

When a concrete mixture is applied around a post driven into the ground for support, it forms a concrete necklace.

Footing

Footings transmit the load of the building to the soil on which the foundation rests. Usually, they are twice the width of the wall they are supporting.

Pier

A concrete column situated on top of a footing that provides support to joists, girders, or posts.

Curing

The process during which concrete is slowly allowed to dry while maintaining a constant level of moisture to prevent cracking.

Rebar

Metal reinforcement bars that are laid inside concrete in a grid design to strengthen the finished concrete structure.

Anchor Bolt

Anchor bolts are used to secure hangers or timber brackets to masonry or concrete.

Sill Anchor

Metal anchors with threads that are fixed in concrete for fastening sills.

Joist Hanger

A support bracket that strengthens the joint between a joist and another framing member is known as a joist hanger.

Batter Board

Batter board is a piece of level timber that is fastened to stakes driven into the ground. It is used to create a string outline for footings and foundations.

Floor Joists

Timber beams spread horizontally on the floor, usually at intervals of sixteen inches, to create the floor frame, are known as floor joists.

Header or Rim Joists

Header or rim joists form the outer perimeter of the shed’s floor frame. They are perpendicular to the floor joists and nailed to their ends.

Sill

The 2×4 timber board attached horizontally to the foundation that supports the shed walls.

Skirt Boards

Skirt boards are pressure-treated 2×6 timber boards that are laid along the ground during pole framing construction.

Subfloor

The OSB or plywood siding that rests on floor joists and supports the main upper shed flooring.

Assembling The Wall Frame

The different framing members involved in the construction of the wall frame are given below.

Battens

The thin strips of plywood that overlap the vertical connections between siding boards are known as battens.

Beam Or Girder

A horizontal piece of lumber used in framing to support the weight of the shed.

Corner boards

Lumber boards fastened to the corners of the shed frame vertically to serve as an ending point for siding boards.

Cripple studs

The short vertical studs that are secured between a sill and a bottom plate or between a top plate and a header.

Top plate

The horizontal timber board nailed across the upper end of wall studs. It forms the upper perimeter of the wall frame where the roof frame will be nailed.

Double top plate

Two pieces of lumber fastened together and nailed horizontally over the top of wall studs.

Full stud

The long vertical lumber that extends from the top wall plate to the bottom wall plate.

Jack stud Or Trimmer

The stud which extends from a header to a bottom wall plate is known as a trimmer or a jack stud.

Girder pocket

The depressed cavity built into the foundation wall into which a girder is fastened.

Girt

In timber framing, the horizontal boards that span across the length of the wall and are used to nail the siding sheets are known as girts.

Soleplate Or Shoe

The wooden board that forms the base of a shed wall frame is known as a shoe or soleplate.

Spring brace

A lumber fragment stuffed diagonally between a wall frame and floor frame and used to fasten a bow into a wall frame.

Shed Roof Framing Components

Constructing a shed’s roof can be tricky. Let us take a look at the typical roof framing members and terms that will be helpful for DIY builders.

Ridge

The horizontal peak of the shed roof is known as its ridge.

Ridge Board

The timber board that is fastened horizontally to the crest of the roof frame is known as the ridge board.

Rafter

Rafters are the primary framing components that form the roof frame.

Jack rafters

The short rafters that are secured at an angle between the top plate and main rafter, usually in a hip roof.

Barge rafters Or Fly Rafters

The final outermost rafters in the roof frame that form the overhangs.

Ridge cut

The cut in the upper end of a rafter which fits into the ridge board.

Bird’s mouth cut

The cut made in the lower end of a rafter to connect it with a top wall plate.

Rise Of Roof

The vertical height between the top wall plate and the highest point in the roof, usually the ridge board.

Run Of Roof

The horizontal length between the outer edge of the top wall plate and the center of the ridge board.

Slope or Pitch Of Roof

The slope of a roof is the rise divided by its run. In a roof that rises six inches for every twelve inches of run, the slope is 6/12

Eaves Or Cornice

The bottom part of the roof that extends beyond the walls and forms an overhang.

Truss

An assembly of timber framing members joined together by nodes to form a single sturdy triangular structure.

Chord

The outer framing members of a truss that form the perimeter are known as chords.

Web

The inner framing members of a truss that connect the chords.

Collar Tie

A horizontal timber board fastened between two rafters to provide additional bracing.

Cupola

A ventilating structure with horizontal slats created into the roof to allow airflow.

Fascia

Sections of trim lumber boards nailed to the bottom end of a rafter to craft the overhang.

Drip edge

A metal flashing installed at the roof edges to carry water away from the walls and fascia.

Gusset plates

Plywood or metal plates that connect the webs and chords in a truss.

Purlin

A horizontal timber board that is fastened below and in between the main rafters to reinforce the roof frame.

Rake Trim Or Gable Trim

The trim boards that are fastened over the fascia on the gable roof ends.

Soffit

The plywood boards that cover the length of the wall beneath the rafters and cover the space between the fascia and wall.

Valley Flashing

Sealing material that prevents leaks at the junction of two sloping roofs.

Gable roof

A double-pitched roof in the shape of an inverted V.

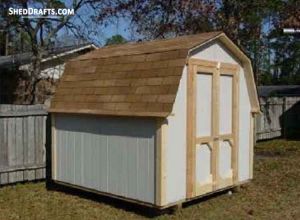

Gambrel roof

A gambrel is a styled barn roof that combines two gable roofs. The lower slope is steep, and the upper one is shallow.

Hip Roof

A roof with four slopes in four directions connecting together at a central ridge.

Installing Doors And Windows

In the last stage of construction, the doors and windows are attached to the wall frame. Some common parts include the following.

Header

The horizontal timber board that is installed over the rough openings inside the door and window frames is known as the header.

Jamb

The vertical portion of a frame onto which the door or window is fastened.

Nailing flange

The extended surface of a component that bears pre-drilled holes for nails or screws. Like the sides of a window.

Apron

A decorative trim installed on the wall below a window still or stool.

Drip cap

The L-shaped molding installed over doors and windows to prevent moisture seepage.

Stool

The bottom horizontal part of a window that looks like a shelf is known as the stool.

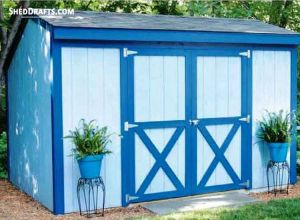

Z-brace Door

Doors constructed by fastening timbers boards together using a Z-shaped brace.

More Essential Shed Building Terms

Oriented-Strand Board (OSB)

Engineered wood produced by compressing layers of aligned wood strands mixed and bonded with adhesives.

Particle Board

Engineered wood crafted by compressing and extruding a mixture of wood flakes and an artificial resin.

Sheathing

Wooden panels, usually made of plywood, that are fastened to the exterior of the shed.

Blocking

The timber installed between framing members like joists and rafters to provide bracing, spacing, or additional nailing surface.

Flashing

Metal, rubber, or vinyl material used to cover and protect exposed joints from the weather.

Board-and-batten siding

A style of installing siding where wide vertical siding sheets known as boards are alternated with narrow strips of siding known as battens. This creates a layered structure that is resistant to harsh weather and looks beautiful.

Center pole

The central post used in pole framing to support the inner framing and roof.

Cleat

A timber board secured to another board or surface to provide additional support.

Face-nailing

Driving nails perpendicularly through the face of timber boards.

Toe-nailing

Driving nails at an angle into the face of a timber board such that they penetrate the adjacent board.

Kerf

The thin-cut a saw blade makes into a piece of timber.

Pilot hole

Holes drilled with an electric drill before inserting a screw or nail to prevent splitting.

O.C (On Center)

Measurements taken from one stud center to the next adjacent stud’s center.

Plumb

Aligned vertically erect at a right angle to a horizontal level line.

Pump Jack Scaffolding

A movable platform that can be raised and lowered similar to a vehicle jack. The platform rests on movable brackets and moves along vertical support poles.

Setback

A building code that mandates that buildings must only be constructed a certain distance away from streets, sidewalks, or property lines.

Penny (Abbreviation: d.)

The measurement unit for the length of nails. For, e.g., 10d nails are 3 inches long.

Common Shed Framing Methods

Platform Framing

Platform framing is a method in which the walls for each floor are constructed one story at a time over decked platforms.

Pole Framing

In pole framing, sheds are constructed on large poles set into the ground at regular intervals to provide vertical support. Usually, this technique is used to build large barns where huge open spaces are needed.

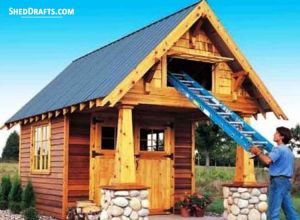

Timber Framing

The timber framing technique is a method for crafting sheds by first building a skeletal framework of large and heavy timbers connected with mortise-and-tenon joints and wooden pegs.

Post-And-Beam Framing

In post-and-beam framing, heavy timber members are used for creating the outer framework, and half-lap joinery with metal fasteners secures the components together.

How To Select The Best Shed Size

Now that you have decided to build a shed the DIY way, it is essential to give some critical thought to how big your shed must be.

First, let us look at the three most common shed sizes that are usually constructed.

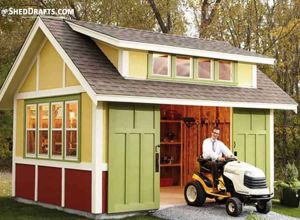

Large (Longer than 20 feet)

The standard size for large sheds is 12×24 or 12×20. This is more of a garage than a shed, and it can hold pretty much anything you want to store. Large riding mowers, bicycles, and even your car! You will definitely need a building permit to build a shed of this size.

Medium (Length around 16 feet)

Medium-sized sheds usually have dimensions of 10×16 or 8×16. This is the most common type of shed that homeowners install in their backyard. You can use it to store large yard tools, a riding mover, and most of the gear you will need all year round.

Small (Length around 12 feet)

A small shed usually measures 10×12 or 8×12. This is the ideal size for a potting shed or a simple garden shed. You can use it to store all your lawn tools, gardening equipment, and flower pots. If all you want to do is empty out the stuff that has been piling in your garage and free up some much-needed space, then this is the right size for you.

You must consider several factors before coming to a final decision on how big a shed you will build. Here are some vital tips that will help you decide the layout of your shed.

Community Building Regulations

Most homeowner associations have restrictions on how big a shed can be built on your property. They will also require you to register the location of your shed with the local zoning office. Large sheds will need a building permit.

Read carefully through your homeowners’ association’s regulations and conditions before you finalize your shed’s size.

Available Yard Space

A large shed will obviously need a large yard. And you need to leave a minimum 6-inch perimeter around your shed, and the foundation should ideally be a foot bigger than the shed’s dimensions. So take this into consideration when choosing a size.

Also, your entire yard may not be level. It is never a good idea to build a shed on sloping land.

Excavating the land and making it level may add significantly to the cost of your shed. Keep this in mind when selecting the shed location.

Your Present Storage Needs

A shed is a great storage solution for any homeowner. Your shed’s size will definitely depend on the kind of gear you want to store in it. If you want to store big items like ATVs and rideable lawn movers, you need a 10×12 shed.

Even small things like sports equipment, power tools, and lawn equipment can quickly add up and make your shed seem overstuffed.

You must also allocate some free space for yourself so that you can move in and out of the building without things falling on you.

Future Room For Growth

A small or medium shed may seem sufficient for today’s needs. But if your shed becomes packed in a year and you run of space, then it would hardly be worth the effort.

Consider your space needs for at least five to ten years in the future before you settle on a size. You may want to turn your shed into a workshop, office, or gym in the future. Or your kids may take up a sport that needs bigger equipment.

Allow your shed to be large enough to accommodate future needs for space.

How To Pick The Best Shed Roof Design

The five most popular shed roof styles are gable, lean-to, gambrel, hip, and saltbox. Let us now look at the advantages and disadvantages of each roof design.

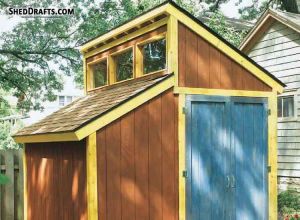

Slanted-Roof / Lean-To Roof

A lean-to or slanted roof is the simplest roof to construct. It is also the cheapest and requires the least amount of materials.

This is the ideal roof style if you are building your first shed.

This roof will require one wall to be taller than the other. Also, it offers very little storage space under the rafters.

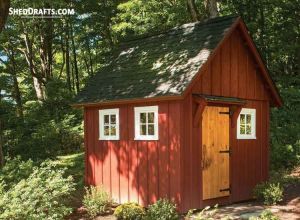

Gable Roof

This is the most common roof design for sheds. It consists of two pitched roofs that meet in the center.

A gable roof is relatively simple to construct, and the overhang keeps water away from the walls.

It is more complicated to build compared to the lean-to roof, but it also offers more storage space underneath the rafters. Strong winds can lift the roof, so it is recommended to use hurricane ties.

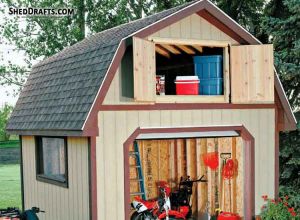

Gambrel Roof / Barn-Style Roof

This is a highly complicated roof design and is not suitable for amateur builders. It provides the maximum amount of attic space underneath the rafters.

A gambrel roof is ideal if you want to build a shed with a loft. This roof can, however, easily get damaged by strong winds and will require the use of hurricane ties.

Hip Roof

A hip roof is the strongest roof design. It offers maximum protection from strong winds and heavy snow.

This is also one of the most complex roof styles and will require significant materials and effort in construction.

Saltbox Roof

The saltbox roof is similar to gable, but as its design is off-center, it provides more attic storage space. It is also more resistant to high winds compared to the gable design.

Extra bracing and more materials will be needed to construct the longer side of the roof, and this will increase cost and efforts.