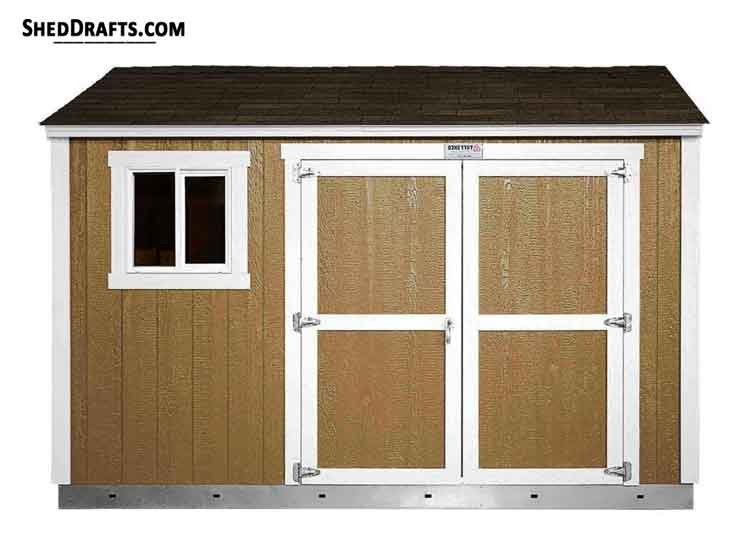

These DIY lean to shed plans and blueprints will help you construct a wooden storage building quickly and within your budget.

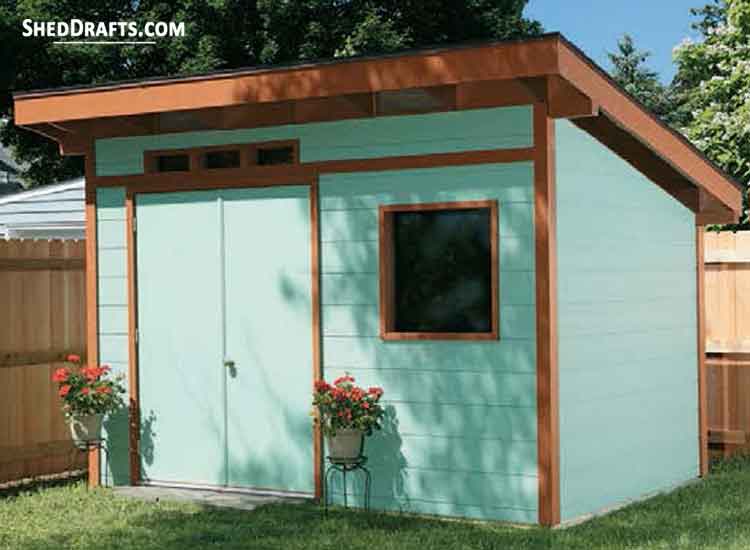

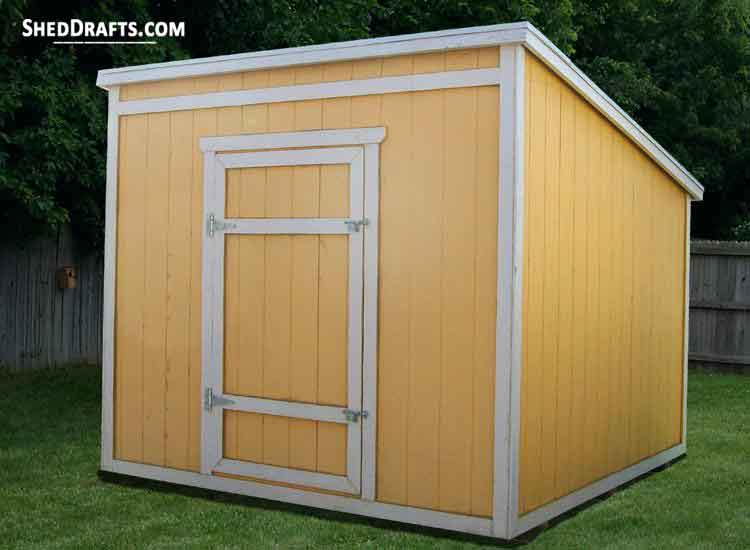

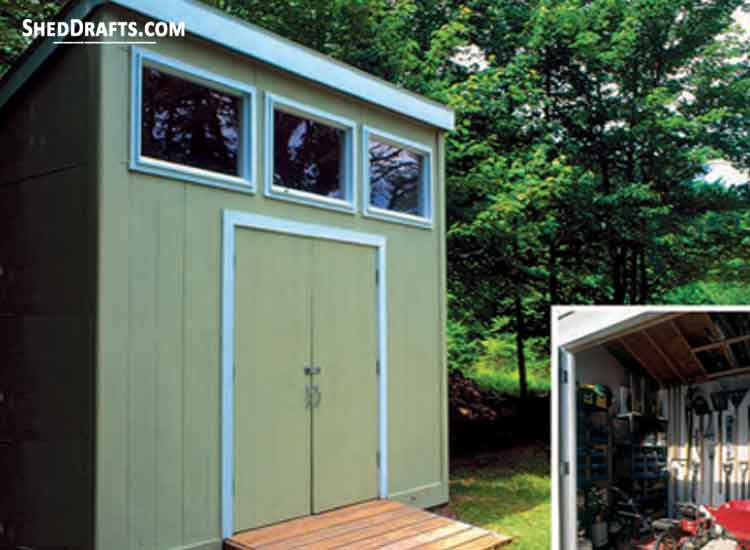

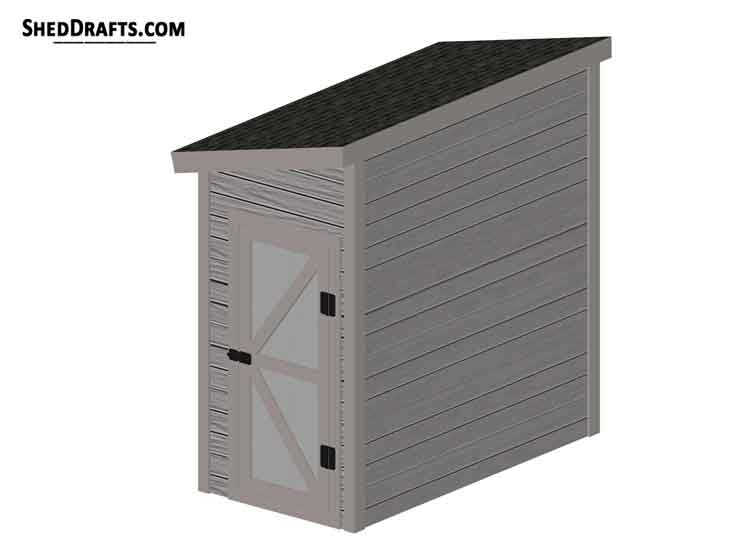

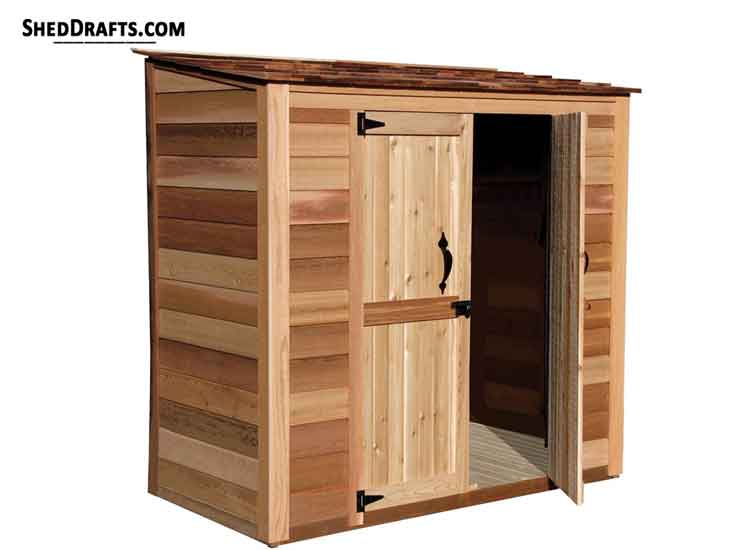

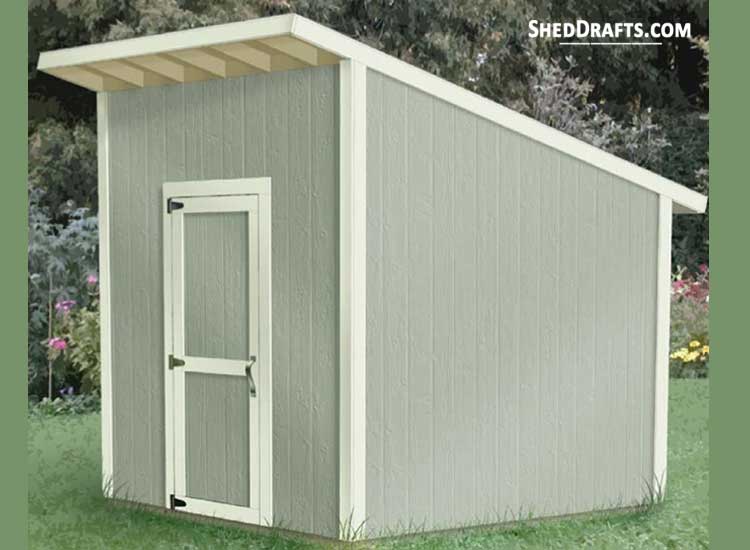

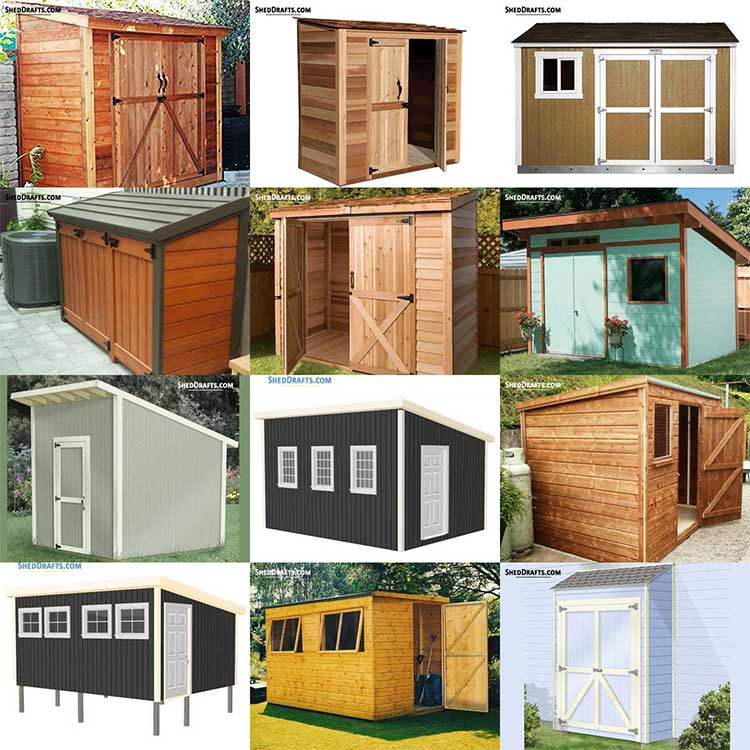

Gallery Of Top Lean-To Roofed Shed Plans

Steps To Assemble a Lean-To Shed

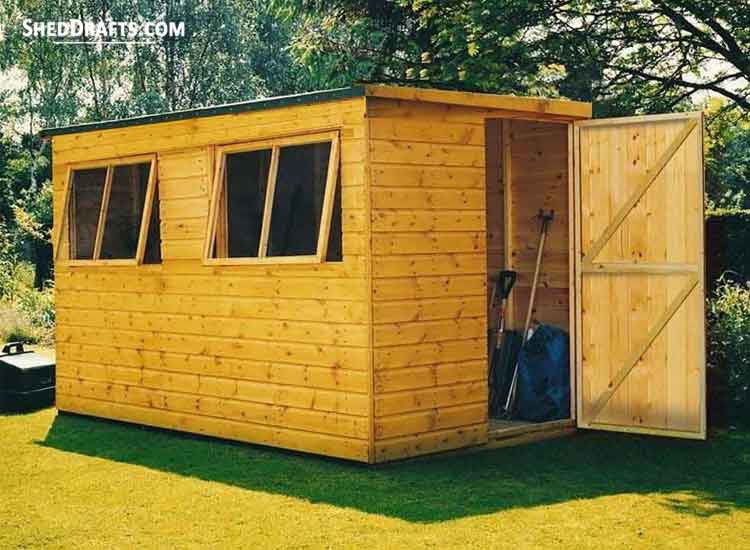

As the name suggests, a lean-to-shed usually leans against an existing structure. They can be crafted as freestanding buildings as well. It is the simplest shed design that can be constructed, and so it is highly practical in function.

This type of shed is mostly used for storage of tools, firewood, and gardening equipment.

As this design has only one slanting roof, the wall at the rear of the roof is left unprotected from water if it is not attached to another building. So it is vital to build the back wall with weather-proof plywood siding.

Here we will look at the steps for crafting a 4 feet by 6 feet lean-to shed.

Materials List

These supplies and materials will be needed for assembling the shed.

- 2×4 Pressure-treated floor joists

- 4×4 Pressure-treated skids

- 2×4 Lumber for rafters, header, studs, bottom plates,

- door framing, nailer, cripple studs, and sub-fascia

- 1×4 Top plate

- 3/4 inch Plywood flooring

- 1/2 inch CDX wall and roof sheathing

- 1×4 Fascia and rake trim

- 1×3 Door trim

- Asphalt shingles

- Drip edge and roofing felt

- Door latch & hinges

- Fasteners and metal framing brackets

- Galvanized nails and outdoor screws

- Stain or paint

Build The Floor

- The floor is built on a foundation of two simple 6 feet long, 4×4 skids.

- You also need to craft two rim joists of the same length with 2×4 pressure-treated lumber.

- Create six floor joists of 45-inch length and nail them among the rim joists at 16 inches O.C. to create the floor frame.

- Place the skids in position on the ground and then align the floor frame over it.

- Check that the frame is square, and then secure the frame to the skids with 16d nails.

- Install plywood flooring sheets over the frame by nailing the panels to the joists.

Assemble Wall Frames

- First, craft the back wall.

- Build 6-inch long bottom and top plates and 8 feet long wall studs.

- Miter the studs at an 18-degree angle at the tops.

- Hoist and fasten the back wall over the floor frame after adding bracing.

- The front wall has two 1-foot-long bottom plates and one 6 feet long top plate.

- The door opening will be four feet wide.

- Create a door header of 51-inch length using 2×4 lumber and fasten them together.

- Craft and install four wall studs of 81-inch length.

- Make 6-inch-long cripple studs and jack studs that are 73 inches long, and fasten them to the header.

- Raise and install the front wall to the floor frame.

- Next, build four 41-inch long plates for the side walls along with 81-inch long studs.

- Secure the studs to the plates and hoist the side wall over the floor.

- Check each wall frame is square and plumb.

- Fasten the corners of wall frames to each other with screws.

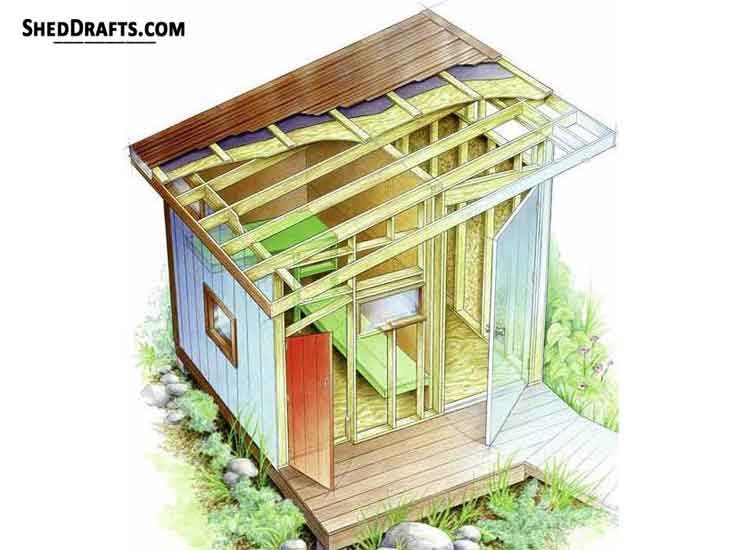

Craft Rafters And Roof Frame

- Rafters are built with 2×4 lumber and laid on the upper plates of the front and back walls to make the roof frame.

- Build four rafters as per the measurements shown in the blueprint and toenail each one to the top wall plates at 24-inch intervals.

- Create gable studs that will attach and support the end rafters onto the side walls.

- Construct sub-fascia and fasten to the rafter fronts and then build and secure the fascia.

Install Wall Siding

- Use weather-proof exterior siding to sheath the walls on all four sides.

- Align the CDX plywood sheet flush with the base of the rim joists.

- Secure the siding with galvanized nails at 6-inch intervals.

- Install siding on the back wall all the wall up to the rafter leaving no gap.

Attach Roof Sheathing

- Install the half-inch thick roof sheathing plywood sheets by staggering the joints.

- Double-check that each rafter is spaced apart at 24 inches and nail the panel to the rafter with galvanized nails.

- Attach rake trim and hide the roof panel edges.

- Now secure the drip edge and attach the roofing felt.

- Next, install the asphalt roof shingles.

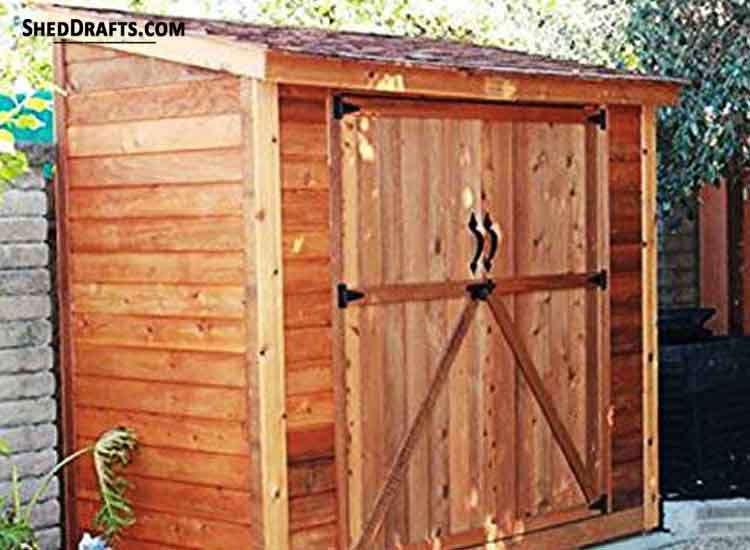

Add Doors

- You can utilize the plywood left over from cutting the opening for the door in the wall siding to craft the doors.

- Install strap hinges and secure the doors to the wall frame.

- Attach a latch on the door.

- Create door trim with 1×3 lumber.

- Attach the trim around the door perimeter and corners.

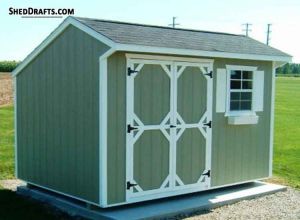

What is The Lean To Roof Shed Design?

A lean-to roof or slanted roof is a single-pitched roof that runs from one wall of the shed to the opposite wall. This is the simplest roof style that any shed can have. Lean-to roofs are sometimes also known as skillion roofs.

Pros Of Slanted Roof Shed Style

Some of the advantages of building a lean-to-shed are as follows.

Easy & Quick Construction

All you need to construct a lean-to roof is to fasten some rafters from one top wall plate to the opposite wall’s top plate. Then install a gable stud in the middle of the rafter securing the center of the rafter to the top plate. Next, attach the fascia and sub-fascia at the rafter ends. Lastly, cover the roof frame with weather-proof siding and secure them to the rafters with galvanized nails.

Lean-to sheds are ideal for novice shed builders as they are relatively easy to construct when compared to other roof styles.

Low Material Costs

A slant-roof shed requires the minimum amount of lumber and accessories for completing the project. The time and effort needed are also considerably less compared to other shed projects. This makes it ideal for DIYers who want to quickly set up a basic shed in their backyard within a weekend’s time on a tight budget.

Easy Water Drainage

If you give the roof a steep pitch, water and snow will easily drain away. The slanted roof design prevents leakages by not allowing water to pool on the rooftop.

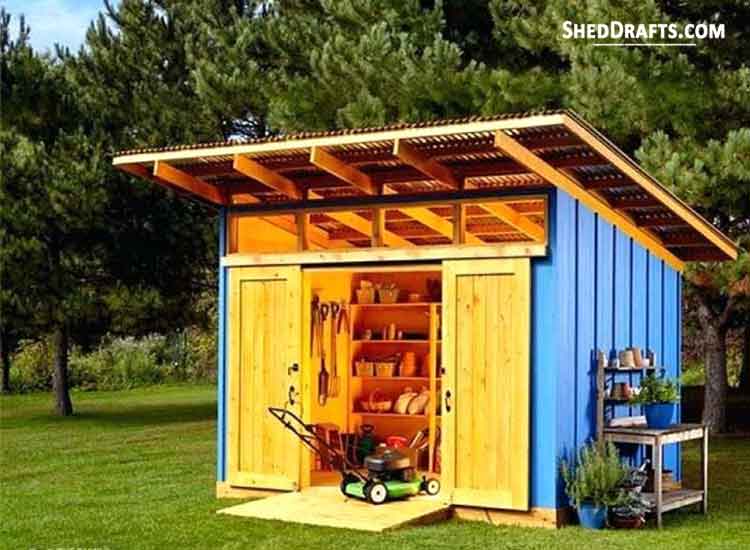

Ideal For Skylights

Skylights can be a great addition to any shed roof. A lean-to shed roof makes it very simple to install one or more skylights. You just need to trace out the perimeter for the skylight on the roof and then cut out the siding. Install bracing along the edges of the opening and then add in the acrylic panel.

A skylight lets in more natural sunlight into your shed than the windows and also makes your building look more beautiful.

Cons Of Lean To Roof Shed Design

Although there are advantages to the slanted roof shed design, it also has its share of shortcomings. Some common limitations of the lean-to roof are as follows.

No Attic Space

The angled design in a lean-to roof leaves very little space underneath the rafters for building an attic. As the ceiling and roof have the same slope, there isn’t much room below the rafters to store anything. If you want extra attic space, then this roof design is not recommended.

Low Wind Resistance

As this roof is supported by fewer rafters and usually has a low pitch, it can easily get blown away during strong winds. If you live in a region with a highly windy climate, then this roof style is not suitable for your shed.

Need For Larger Gutters

Water may drain away very quickly from a slanted roof, but since there is only one roof surface, the speed of drainage may be too fast for normal gutters to handle. If it rains very heavily, then it can cause the gutters to overflow or the water to get collected at the lower drip edge. Hence you need bigger gutters to handle water drainage if you receive heavy monsoons in your area.

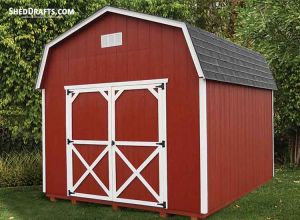

Not Aesthetic

While a single slant roof is a minimalist and efficient approach to shed construction, it may lack the aesthetic appeal of other roof styles. You may want your shed to be both beautiful as well as functional. In such cases, a gable or gambrel roof style might look more classy and traditional.